Back pressure valves are designed to enhance pumping system performance by applying a continuous back pressure to the pump, while also acting as an anti-syphon valve.

Diaphragm back pressure valves apply positive discharge pressure to a metering pump system to improve the consistency of dosage rates by shielding the pump from fluctuating downstream pressure. The diaphragm is held against the valve seat by an internal spring. When the preset pressure is exceeded, the diaphragm is forced up and system fluid flows through the valve to the injection point.

NO MORE CHATTER

Most back pressure valves are based on a pressure relief design where the valve is normally closed. When a set pressure point is reached, the valve opens quickly with maximum flow to relieve pressure. This action doesn’t work well for back pressure valves that need to flow continuously to hold pressure upstream. When the valve opens quickly, pressure upstream drops rapidly and the valve slams closed. The sudden stop in flow causes a pressure spike that forces the valve open again. In a back pressure valve application, this cycle occurs many times per second, creating a loud, chattering valve with inferior performance and a shorter service life. Blacoh’s patented valves with flow stabilization technology meter flow when the valve opens to minimize the pressure drop that initiates this cycle. The result is a valve that doesn’t chatter, performs better, and lasts longer.

- Unique flow stabilization technology improves flow, extends service life, and eliminates valve chatter.

- Internal swiveling spring seat ensures spring force is applied evenly over the diaphragm for more consistent and complete valve closure.

- Both plastic and metal valves feature a separate ring attachment for more uniform clamping load and improved seal performance.

- Threaded connections on plastic valves eliminate the need for metal fasteners that can corrode.

- Proudly made in the USA

BODY MATERIALS: PVC, Polypropylene, CPVC, PVDF, 316L Stainless Steel; additional materials on request

VALVE TOP: PVC, CPVC, 316L Stainless Steel

DIAPHRAGM MATERIALS: EPDM, PTFE

INLET SIZES: 0.25" (8mm), 0.375" (10mm), 0.5" (15mm), 0.75" (20mm), 1" (25mm), 1.5" (38mm), 2" (51mm)

INLET TYPES: NPT, BSP, Flange, Socket Weld, Union, 150# Flange

SPRING PRESSURE: 5-150 psi, 5-50 psi, 5-250 psi on valves up to 1", 50-350 psi on metal valves

CERTIFICATIONS & TESTING: ATEX, NSF, ARRA, 3.1 Cert, Cert of Origin

DIMENSIONS

| Valve Dimensions |

2 Port 180° |

3 Port, 2 Port 90° |

Size

(NPT) |

B

(Dia) |

D

(Flat) |

A |

C |

A |

C |

Mini

1/4" to 1/2" |

2.47" |

2.30" |

4.24" |

0.85" |

4.49" |

1.09" |

| 1/2" to 1" |

3.47" |

3.22" |

5.47" |

1.00" |

5.72" |

1.20" |

| 1 1/2" |

4.47" |

3.92" |

8.07" |

1.38" |

n/a |

n/a |

| 2" |

5.49" |

4.88" |

9.76" |

1.75" |

n/a |

n/a |

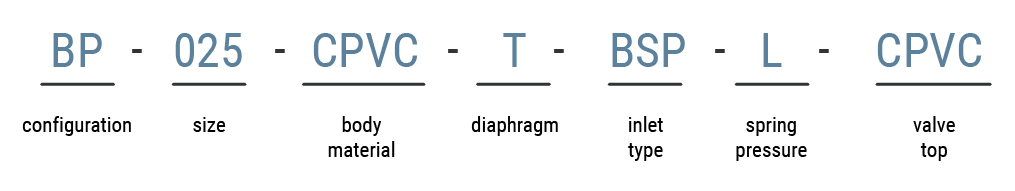

MODEL NUMBER FORMAT

Example model number:

| Field |

Option |

| Configuration |

2 Port 180° (BP), 2 Port 90° (BP90) |

| Size |

1/4" (025), 3/8" (038), 1/2" mini (049), 1/2" standard (050), 3/4" (075), 1" (100), 1 1/2" (150), 2" (200) |

| Body |

PVC (PVC), Polypropylene (PP), CPVC (CPVC), PVDF (PVDF), 316L Stainless Steel (SS) |

| Diaphragm |

PTFE (T), EPDM (E) |

| Inlet Type |

NPT (none), Socket Weld (SW), BSP (BSP), Flange (F), Union (U), 150# flange |

| Spring Pressure |

5-150 psi (none), 5-50 psi (L), 5-250 psi valves up to 1" (M), 50-350 psi metal valves (H) |

| Valve Top |

PVC (none), 316L Stainless Steel standard on 50-350 psi high pressure valves,

CPVC (CPVC) and 316L Stainless Steel (SS) available on request |

FLOW INFORMATION

Flow at 150 psi pressure drop across valve.

| Size |

US GPH

(Pulsating) |

US GPH

(Continuous) |

| 1/4" |

240 |

12 |

| 3/8" |

260 |

13 |

| 1/2" mini |

288 |

14 |

| 1/2" standard |

600 |

30 |

| 3/4" |

640 |

32 |

| 1" |

710 |

36 |

| 1 1/2" |

1500 |

75 |

| 2" |

2000 |

100 |